Norbec Manufacturing Facility: Strengthening Ontario’s Industrial Capacity

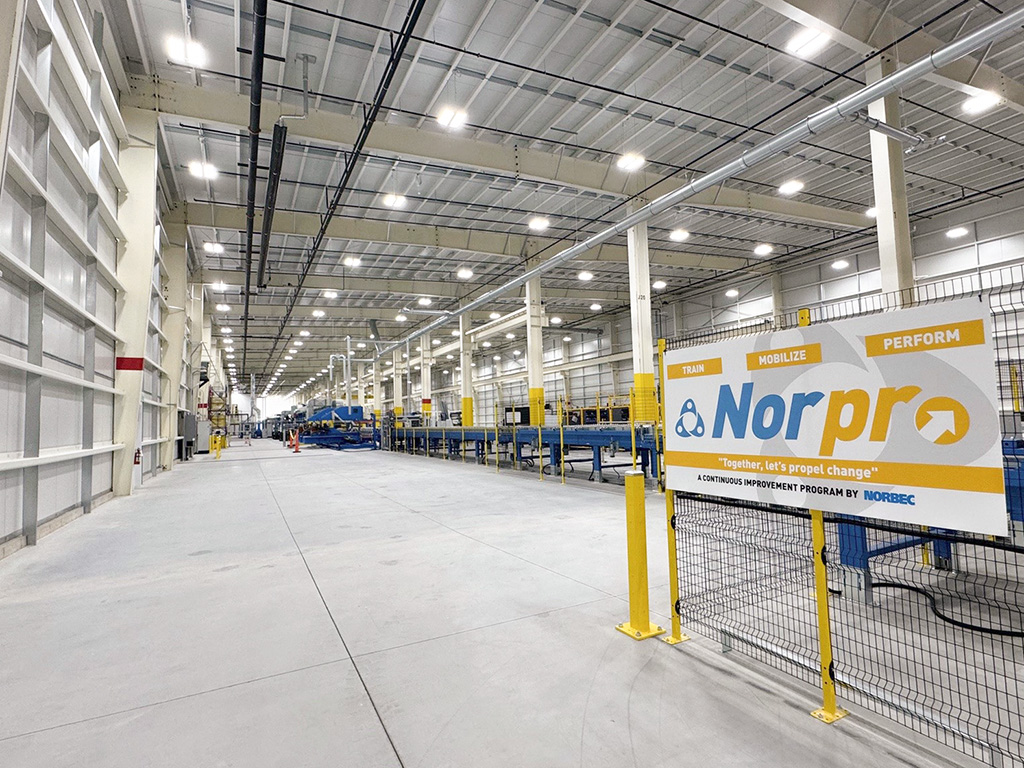

Norbec’s new Strathroy facility officially opened in September 2024, marking the start of local production for its insulated metal wall panels serving Canadian markets.

Located at 990 Wright Street in Strathroy, Ontario, the project brought together a 150,000 sq. ft. manufacturing plant and a 15,500 sq. ft. two‑storey office under one roof. Constructed by Vicano Construction Limited as General Contractor, the development established a dedicated Ontario base for Norbec’s growing operations.

Constructed in approximately 14 months, the facility expands Norbec’s manufacturing capacity while strengthening regional supply chains and showcasing the company’s ongoing investment in Canadian production.

Design Team

This achievement was made possible by our talented design team:

Electrical

Electrical

Project Manager

Mechanical

Our Client: Vicano Construction

Founded in Brantford, Ontario, Vicano Construction is a multidisciplinary construction and development firm with more than four decades of experience delivering commercial, industrial, and institutional projects across the province. The company is recognized for its integrated approach combining project management, construction, and design‑build services to bring complex developments from concept to completion with efficiency and precision.

For the Norbec Manufacturing Facility, Vicano oversaw all aspects of construction and coordination, ensuring that the plant and office spaces met the client’s performance expectations while maintaining schedule and quality standards. Their expertise in managing large industrial builds made them a strong partner in realizing Norbec’s new Ontario manufacturing base.

Norbec Ontario’s Challenges and Opportunities

Designing a modern industrial facility for insulated metal panel manufacturing required careful coordination between production requirements and administrative functions. The project joined a 150,000 sq. ft. manufacturing plant with a 15,500 sq. ft. two‑storey office, each with distinct system needs and operational demands. Clear communication between disciplines and close collaboration with Vicano were key to achieving completion within the 14‑month construction schedule.

Norbec Ontario’s Technical Highlights

Mechanical Highlights

- Radiant tube heaters provide primary heating throughout the production area.

- Gas-fired make-up air units serve the process equipment, including one unit dedicated to the building’s dust collection system.

- Piping was designed to connect new process equipment and the small plant office.

- The production area includes a small laboratory served by a dedicated HVAC unit with enhanced filtration and positive pressurization to minimize contaminants from entering.

- Equipment locations and service zones were arranged for accessibility and to accommodate potential future expansion.

- The office area included five roof top units and a centralized energy recovery system to provide ventilation to the office areas.

Electrical Highlights

- A 4,000A service to power the first phase, with the potential for a second phase of the same size. Once phase 2 is completed, the electrical system will provide redundancy where either service can feed the main building and maintain production.

- The main transformer provided distribution power at 480Y/277 V to feed the process equipment, most of which was imported from outside the country.

- Provisions for electric‑vehicle charging stations were incorporated to support evolving operational needs.

- Tie‑ins and wireways for future solar power integration were included in the electrical design to enable sustainable energy options.

- Fire alarm and communications boards were installed in accordance with the Ontario Electrical Safety Code, ensuring safe and reliable facility operation.

Looking Ahead

The Strathroy facility reinforces Norbec’s presence in Ontario’s manufacturing sector, offering local capacity for insulated metal wall panel production and supporting continued growth in the region’s industrial base. For Callidus Engineering, this project reflects a successful partnership with Vicano Construction, delivering an efficient, technically sound facility designed to serve both the client and community well into the future.

Gallery