Carpenters Union Local 249 Training Facility: A training centre celebrating craft, community, and the future of skilled trades

Completed in 2021, the Carpenters Union Local 249 Training Facility is a 24,000 square foot centre designed to expand the Local’s training capacity and support members at every stage of their careers. The new building brings together classrooms, industrial‑scale shops, administrative spaces, and gathering areas in a single purpose built facility.

The project reflects the growing needs of Local 249 and the wider trades community. The facility supports apprenticeship programs, skills upgrading, pre‑apprenticeship training, and safety certification courses delivered throughout the year. It also provides space for meetings, events, and activities for members and their families.

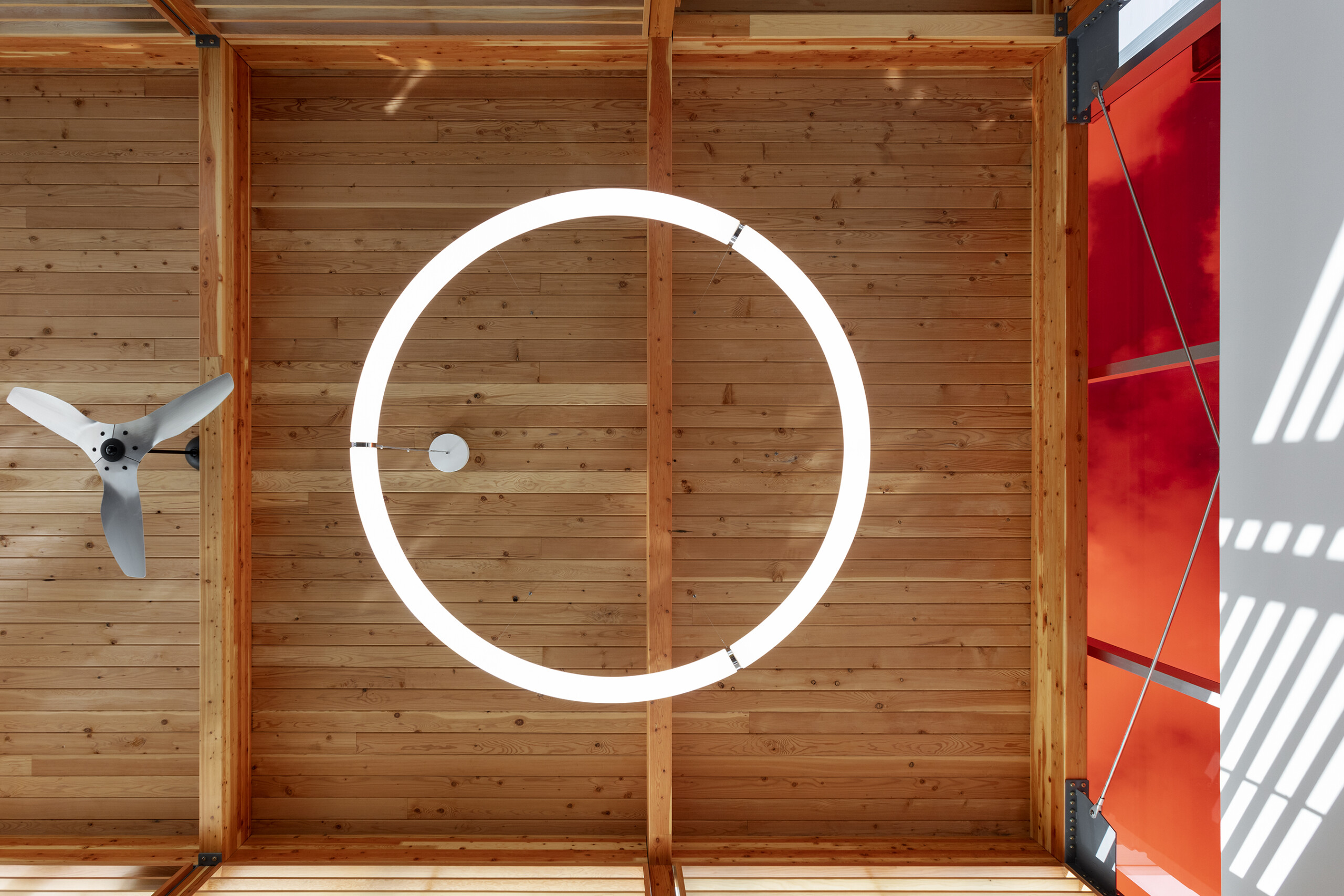

The building itself acts as a teaching tool. Heavy timber structure, specialty millwork, custom doors, and detailed wood finishes showcase the craft that defines the carpentry profession. The architecture uses both traditional and modern techniques, reinforcing the Local’s dedication to building excellence.

Design Team

This achievement was made possible by our talented design team:

Mechanical

Project Manager

Electrical

Electrical

Our Client: Shoalts and Zaback Architects Ltd.

Shoalts and Zaback Architects Ltd. is one of Kingston’s most respected architecture and design firms. Founded in 1990, the firm has grown into a versatile practice offering full-service architecture, interior design, space planning, and master planning across a wide range of building types. With a track record of award-winning work and deep experience in educational, institutional and community-focused facilities, SZA brought the right combination of design-craft, technical rigour and client-collaboration to this project. Their commitment to celebrating woodworking and skilled trades in the building’s architecture makes them the ideal partner for this mass timber project.

Reflections From Shoalts and Zaback Architects Ltd.

“Working with Callidus Engineering is always a steady, collaborative process. Their team approaches every project with a clear focus on coordination, technical clarity, and what is best for the client. On a building like the Carpenters Union Local 249 Training Facility, that approach mattered. The program was diverse and the systems were complex, and Callidus helped bring the design intent to life in a way that supports both the training environment and the people who use it every day. It was a strong partnership and a project we are proud to have led alongside them.“

–Gerry Shoalts, Founder & Senior Architect, Shoalts and Zaback Architects Ltd.

Local 249 Challenges and Opportunities

The training centre required a design that could support diverse instructional needs under one roof. Industrial training areas needed to operate safely alongside classrooms and administrative offices. Mechanical and electrical systems needed to serve high bay spaces, high ventilation requirements, and specialized equipment, while maintaining comfort and efficiency throughout the building.

Careful coordination was required to integrate the overhead crane, woodworking shops, welding equipment, dust collection systems, and various instructional stations. The design also had to accommodate specific code requirements, including CSA B149.1 clauses governing combustion air and ventilation openings, gas service coordination, and the safety systems typical of training environments.

Outdoor spaces were incorporated as active work areas, requiring additional planning for site lighting, power distribution, irrigation, and future service expansion. These elements give the Local flexibility for future training needs.

Local 249 Technical Highlights

Mechanical Highlights

- Four rooftop units selected and zoned to serve both the high bay training hall and the administrative wing, with capacities matched to stratification, heat gain, and ventilation demands typical of industrial‑education hybrid facilities.

- A dedicated make‑up air unit with plate heat exchanger providing tempered, code‑compliant ventilation for woodworking, welding, and shop environments, balanced to maintain safe negative pressure relationships.

- Radiant tube heaters installed in the workshop spaces to deliver responsive heating without disrupting overhead crane operations or creating air movement that affects dust collection performance.

- Natural gas service engineered with appropriate pressure adjustments, coordination with Enbridge, and clear definition of inlet limitations for RTUs to ensure compatible operating pressures and stable delivery under full equipment load.

- Plumbing design including hot water recirculation, thermostatic mixing valves, expansion control, floor drains, emergency fixtures, and shop‑specific supply and waste connections sized for instructional workflows.

- Ventilation in the mechanical room including coordinating openings, baffle separation between combustion air and ventilation air, and updates to comply with CSA B149.1 clearance and cross‑sectional area requirements.

- Domestic water systems serving classrooms, washrooms, showers, and break areas, with distribution sized for simultaneous instructional use and peak occupancy.

Electrical Highlights

- Electrical service sized to support a training‑intensive facility, including an 800A, 208Y/120V three‑phase main distribution panel feeding multiple subpanels for classrooms, shop equipment, crane systems, and administrative areas.

- Dedicated branch circuits added for door operators, high‑capacity hand dryers, and specialty instructional loads, ensuring equipment performance without overloading shared circuits.

- Exterior site lighting designed with dark‑sky‑compliant LED pole fixtures, wall packs, and recessed luminaires, all controlled by a coordinated timeclock to maintain site visibility and safety while reducing energy use.

- Infrastructure for future exterior electrical expansion, including spare conduits and power/data rough‑ins at designated parking locations.

- Security systems including CCTV cameras at entrances and shop areas, access control devices, card readers, and door hardware power supplies, all tied into the facility’s low‑voltage network.

- Emergency and exit lighting throughout the building, including battery‑backed luminaires, combination exit/emergency heads, code‑compliant coverage for both high‑bay and enclosed spaces, and circular light fixtures designed by our team.

Community Impact

The facility has earned recognition for its architectural and material excellence, including honours from the Ontario Wood WORKS! Awards and the City of Kingston’s Livable City Design Awards. These awards highlight the quality of the design and the way the building celebrates carpentry through its structure and detailing. Congratulations to Shoalts and Zaback Architects for their outstanding work and well‑deserved recognition.

By expanding access to apprenticeship programs, safety certification, and hands‑on technical training, the facility strengthens the skilled trades ecosystem across the region. Its purpose‑built spaces support new entrants to the trade and provide opportunities for experienced members to continue developing their skills, contributing to a stronger, more resilient construction community.